Budding Partnership

Alumni best friends introduce high-efficiency water treatment technology to medical marijuana cultivation center

to create a more sustainable environment to hydroponically grow medical cannabis in his company’s new 80,000-square-foot facility.

Michael Boyd, ’05 | Senior Sales Manager, Desalitech

Michael Williamson, ’07 | Plant Manager, Kind Love

By Angie Lewis, ’03

Michael Boyd, ’05, doesn’t remember the first time he met Michael Williamson, ’07, but he knew they’d become great friends after a discussion about a soccer match on TV spilled out into the parking lot of the former Underground Bluz, near UCF, for a real game.

“Those impromptu games became late-night traditions throughout the remainder of our college years, and afterward,” says Boyd, who earned his bachelor’s degree in engineering technology.

The guys would eventually become the best of friends, even as their career opportunities later took them more than half a country apart.

Based in Newton, Mass., Boyd serves as the senior sales manager for Desalitech, a $20-million organization that manufactures high-efficiency water treatment and wastewater reuse products.

About six years ago, the company started in Israel, a country built on the outskirts of a desert, with limited access to available water resources, which is why it has become one of the leading water treatment hubs on the planet.

“Between 1930 and 2000, the world population tripled from two billion to six billion, and by 2050, it will reach nine billion,” Boyd explains. “Increased production of food and energy, along with rising economies and industrialization, are all increasing the demand for water. Yet, water resources are overwhelmed, and many are already depleted from overutilization, which leaves desalination and water reuse as the only available new sources of water.”

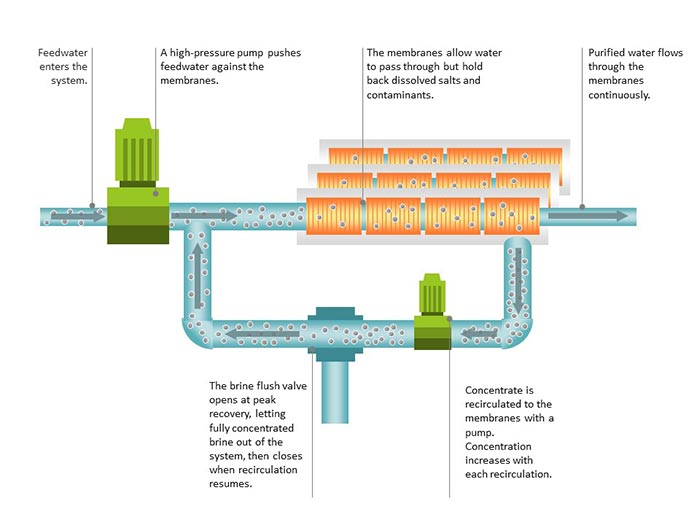

He says industry is responsible for nearly 60 percent of fresh water withdrawals in the U.S. and in other developed countries, with agriculture accounting for an additional 30 percent. He adds that while reverse osmosis is widely applied for water purification, traditional RO systems can create excess brine waste, do not use water supplies efficiently and consume too much energy.

In contrast, Desalitech’s ReFlex RO systems, featuring Closed Circuit Desalination™ technology, reduce brine waste by up to 75 percent and energy consumption by up to 35 percent, compared to traditional RO designs.

Based in Denver, Co., Williamson is the plant manager for Kind Love, a medical marijuana dispensary, which also includes an 80,000-square-foot hydroponic cultivation center.

Williamson, who graduated with a bachelor’s degree in interdisciplinary studies, was diagnosed with multiple sclerosis his freshman year of college.

“[The MS] caused me to be temporarily paralyzed from the waist down,” Williamson explains. “With the uncertainty of my future personal health, I changed my major to interdisciplinary studies with a focus on digital media. My thought process at the time was, if I was going to be in a wheelchair from time to time, or permanently, I wanted to make sure I could work, earn, create and contribute to an organization. Digital media gave me the ability to be able to work on a computer from anywhere.”

After many lackluster visits to medical dispensaries as a patient, he and his partners were inspired to create Kind Love in 2009. He says they saw much room for improvement and recognized an opportunity to help the underserved market of women and seniors.

“The cannabis plant is made up of chemical compounds called cannabinoids,” he explains. “Though scientists aren’t exactly sure, it’s estimated that there are at least 85 cannabinoids that make up the cannabis plant. The most well-known and popular cannabinoid is tetrahydrocannabinol, or THC. Though THC has medicinal benefits, particularly with gastrointestinal issues and inflammation, it’s most commonly characterized by a psychoactive effect, which is described as a relaxing and cerebral high.

“Currently, most Colorado analytical labs have standards and are testing for four to 12 of the 85 cannabinoids. Thanks to legal access to these analytical labs, the medical community started to notice rare strains of cannabis that were extremely low in THC and elevated in cannabidiol, or CBD. Through selective breeding techniques, cannabis breeders have managed to create new varieties with high levels of CBD and little to no THC.

“After my first high-CBD discovery at our research and development cultivation facility, we started hunting for more high-CBD genetics through breeding and acquisitions with other medicinal breeders. Unlike THC, CBD has no high or mind-altering effects. It’s a non-psychoactive and has a huge range of medicinal benefits and properties, such as antiemetic, anticonvulsant, antipsychotic, anti-inflammatory, antioxidant, anti-tumor, anti-cancer and antidepressant.”

In fact, Kind Love holds the record for the highest CBD ever recorded, and is helping to treat patients with cancer and MS, as well as children with seizures, and many more. Williamson is working with CNN’s Dr. Sanjay Gupta on many of these high-CBD projects, which should produce results later this year.

While he respects soil growing, Williamson says Kind Love grows its plants hydroponically because it offers more environmental control and sterilization for large-scale cannabis agriculture.

“People forget that organic soil is organic — meaning it’s full of beneficial and non-beneficial bacterias, molds, fungi, and various insects, which can cause serious damage to cannabis crops if not controlled appropriately,” he says.

When the company was in the process of building its new cultivation facility last year, Williamson researched reverse osmosis machines. The best one he could find on the market was recovering 75 percent good water, with 25 percent going to waste. His previous cultivation facilities were operating at 33 percent good water, with 67 percent waste.

Realizing he was looking at the wrong technology, he looked at Desalitech’s ReFlex reverse osmosis system with CCD technology, which would give him 93 percent good water recovery, with only 7 percent wastewater.

Williamson says his friend was originally doing him a favor, since Boyd thought Kind Love’s operation was probably too small to utilize his company’s system, but he flew to Denver anyway to calculate the numbers. To their delight, Kind Love’s new cultivation facility qualified for Desalitech’s smallest full-scale system, which is commonly used as a pilot for large power plants.

“Michael Boyd and I both demand the absolute best of the best when it comes to our projects, and where and with whom we invest our time and money,” Williamson says. “Of course, it was very cool to do business with a dear friend and colleague, but, more importantly, I knew that I had one of the best systems that money could buy, because I knew he wouldn’t associate with or be a part of anything less. I am very grateful for his friendship, his strong communication skills and ability to execute. His general demeanor and hard work ethic continue to inspire me every day to work harder, smarter and faster.”

More Info

Meet Kind Love medical marijuana dispensary’s plant manager, Michael Williamson, as he explains his decision to partner with best friend Michael Boyd’s water treatment company, Desalitech: